Application technology

The application technology consists of the interaction between the paint atomizers, automatic motion machines/robots, color changing, dosing and mixing technology and paint supplies, tailored to the paints used, paint quantities, coating times, components, conveyor and cabin technology. The multitude of different requirements and the necessary process technologies create an almost endless variety of variants. The LacTec atomizers are just one, but a central, element in the application technology. They contain a wide variety of colors and flushing valve technology, adapted to the respective requirements.

The paint atomization

For application to the workpieces to be painted, the paint is atomized into the finest droplets. With electrostatic atomizers it is also charged electrostatically and is therefore “magnetically” attracted to the grounded workpieces. This procedure enables a very high application/transfer efficiency.

Which paint sprayers does Lactec produce itself and what are they used for?

We at Lactec see ourselves as a provider of automatic painting systems. Our goal is to develop an industrial, fully automatic painting process, optimized to your needs. Our automatic atomizers are designed/adaptable for use with multiaxis robots or for mounting on 1/2 axis robots.

Compressed air atomizing gun (with/without e-statics)

The airstatic gun is a compressed air atomizing gun with an electrostatic charge on the atomized paint. It can also process water based paints electrostatically and can be operated with the same TCP (Tool Center Point) as a Pico Bell (high rotation bell). The AirStatic Gun is used on painting robots. Preferably when the workpiece geometry is relatively complex or a metallic effect must be achieved using an air-atomizing gun.

High rotation bell atomizer (with/without e-statics)

The picoBell is a high-end high-rotation atomizer for painting robots. It has an air-bearing turbine that rotates up to 70,000 rpm, a double steering air ring and can be operated with or without high voltage. The picoBell has a modular structure and can therefore be perfectly designed to suit the respective customer needs. Integrated 2K mixer? A/B paint feed? Piggable right into the atomizer housing ? Everything is possible. The picoBell is used on painting robots. Especially for high-quality surfaces, such as automobile bodies and their add-on parts. But the picoBell also achieves perfect paint finishes in other industrial sectors , e.g. for cardan shafts, motorcycle tanks and shock absorbers .

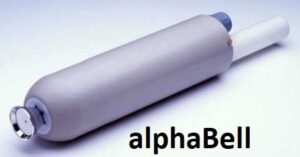

High rotation bell atomizer (with/without e-statics)

The alphaBell is still our “workhorse”. A robust electrostatic high-speed rotary atomizer for general industry. It can be found wherever high atomizer speeds and great controllability of the spray pattern are not required.

High rotation disc atomizer (E-Static)

The powerDisc is an electrically powered disc atomizer used in Omega cabins. It is unique in the world in terms of its low operating costs, because it does not require expensive compressed air for the speed. It can be equipped with spray disks of different diameters. The powerDisc is ideal for processing water-based paints . The powerDisc is used for painting shock absorbers, bicycles, profiles and other workpieces that can be hung vertically.

High rotation disc atomizer (E-Static)

The alphaDisc is a pneumatically driven disc atomizer , also for use in Omega cabins. Its advantage: It is relatively inexpensive in terms of investment costs and is easy to use even by less qualified personnel. The alphaDisc is used, for example, for painting bicycles, gas struts, toy cars and also for painting the inside of barrels.

What methods of paint atomization do exist?

The most common method of spraying paint is with compressed air spraying guns. A jet of paint emerging from a nozzle is atomized with the help of compressed air, which emerges at high speed from bores arranged concentrically around the paint nozzle . The vast majority of manually operated paint guns work according to this principle. Automatically controlled compressed air guns are also widely used.

Airless guns work with a different physical atomization principle . They atomize the paint by pressing it through a small, elliptical-shaped nozzle ( diameter approx. 0.5-1 mm) at high pressure (from 50 – 150 bar). Airless paint guns are preferred for painting large areas with large amounts of paint per unit of time. Airless guns are available for manual and automatic coatings.

In the 1950s, so-called purely electrostatic atomizers were also developed. The paint was fed to a sharp edge to which high voltage (90-140 kV) was applied. A strong electric field formed between the sharp edge and the grounded workpiece. These field forces cause the paint to atomize into tiny drops, it becomes electrostatically charged and then attracted to the grounded workpiece. The paint droplets travel along the electrical field lines towards the workpiece. This achieves a very high application efficiency. However, this process also has a number of disadvantages (Faraday cages cannot be painted, water-based paint is not atomized, etc.), which is why it is rarely used in its “pure” form today.

In order to overcome the disadvantages of purely electrostatic painting technology, high-rotation atomization was developed. Rotating, bell-shaped or disc-shaped atomizers were designed, which, using high voltage, mechanically atomize the paint through their high rotation frequencies and charge it electrostatically through contact or ionization. They can also be used to achieve a high transfer efficiency, although this depends on the workpiece geometry and the atomization parameters. High rotation atomizers are only used in an automatic function.