Paint supply

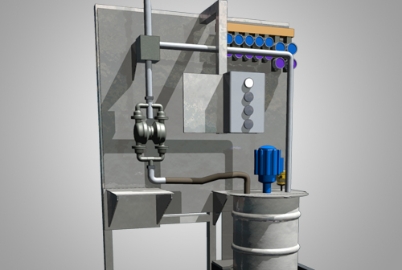

The painting process begins with the delivery of the paint to the paint supply room. From the processing of very small quantities (low runner) to so-called “high runner” systems with delivery containers of up to 1000 l, everything has to be processed and reliably transported into circular lines or stich pipe systems using appropriate feeding pumps.

The ease of use and monitoring of the paint supply systems must meet the high quality assurance standards.

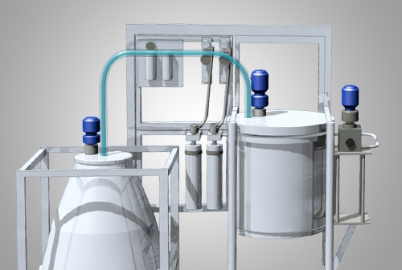

A paint supply has other complex tasks to fulfill. For example, stirring up or keeping paint material in suspension using agitators.

It is also necessary to monitor the fill levels of each container, to filter the paint according to specifications and to exactly dose the paint components. A simple exchange of delivery containers with the support of pneumatically operated lid lifters must be guaranteed, as well as safe electrical isolation when using electrostatics.

To process the entire range of paints, hardeners and detergents, we supply you with material supplies tailored to your requirements for all common container sizes as well as special solutions.

These systems are designed customer-specifically, optimized for your processes and requirements!